It’s already impossible to imagine our society without electric cars. The past two decades we have seen enormous leaps in the development of electric vehicles. Whereas the first modern electric cars had a range of 200 kilometers, for the latest generation it is quite normal to drive at least 500 kilometers carefree.

In the trucking industry, emission-free operation is also high on the agenda. The truck industry goes much further than only developing electric trucks. A great example of this is the electric PTO (E-PTO). In this blog article, we’ll take a closer look at that.

PTO

To learn a little more about E-PTO, it might be helpful to first talk about the ‘normal’ PTO. PTO is the abbreviation for ‘Power Take Off’.

The PTO takes its power from the engine or the gearbox of the vehicle. This means that the engine must always be running when you want to use the PTO.

The applications of a PTO are extremely versatile. You can use it to drive a truck mounted crane or a concrete mixer, but the engine of the vehicle must always be running.

Among other things, you can drive a concrete mixer with a PTO

E-PTO

Unlike the regular PTO, an E-PTO is not driven by the vehicle’s internal combustion engine, but by an additionally mounted electric motor. The use of an E-PTO brings a number of enormous advantages:

-

- Less harmful emissions

-

- Less noise pollution

-

- Fuel savings

In addition to these advantages, it’s also true that the engine of the vehicle makes fewer hours, and therefore has a longer life. After all, 1 hour of operation of an internal combustion engine is equal to 50 kilometers travelled.

The use of the E-PTO is being applauded in the construction sector in particular. Due to the current climate policy, CO2 emissions from companies must be drastically reduced. The maximum emissions for a large construction project are laid down in the building contract documents, as is the maximum noise pollution in decibels.

When all trucks delivering materials to a construction site use an E-PTO, this already represents an enormous CO2 reduction for a construction project. Think for example of concrete mixers, sand tippers, and truck-mounted cranes. It’s also safer. For example because you can hear each other much better when you’re around an operating truck crane.

An E-PTO is safer because, among other things, you can hear each other much better when you’re around an operating truck crane

Applications

The applications of an E-PTO are actually just as versatile as a regular PTO. From truck mounted cranes to aerial work platforms, and from concrete mixers to vacuum tanks, everything that’s driven with a PTO can also be driven with an E-PTO.

It’s even possible to retrofit this to an existing truck. However, an increase in weight must be taken into account, and there must be sufficient space on or near the chassis to install the installation.

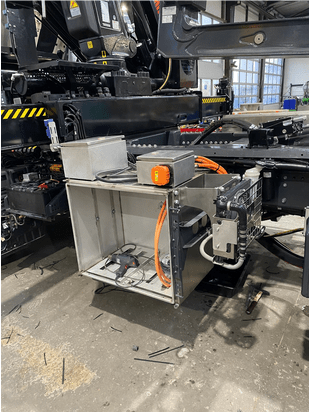

On the photo you can see the box on the chassis where the battery pack will be placed

Weight

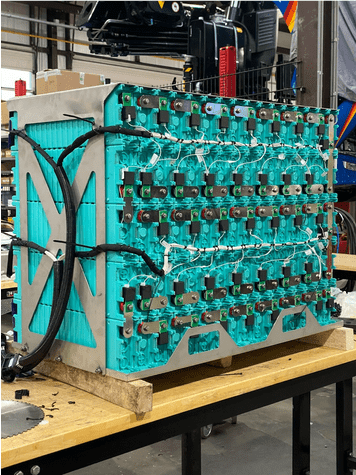

The E-PTO is powered by a battery pack consisting of all separate cells, so a broken cell can be easily and quickly replaced. The battery pack is neatly built into a watertight stainless steel box, and this is mounted on or to the chassis.

A complete package including the electric motor can have a weight starting at 450 kg. A hybrid application is often chosen, in which an E-PTO and a conventional PTO are built onto a truck. Should the batteries of the E-PTO run out, the driver can still finish the job.

In some cases, instead of using the truck’s internal combustion engine, an additional built-up combustion engine is used. Think of a concrete mixer-trailer or a stone trailer with a rolling crane. These engines can be replaced with an entire electric package without any problems, and in this case there’s no weight increase.

The photo below shows a battery pack that is almost ready for installation

Wierda Hybrid Technologies

For this article I visited Wierda Hybrid Technologies in Joure (the Netherlands). Within this branch of the Wierda group they are, among other things, engaged in building and maintaining electrical PTO installations on a large scale. Do you want more information about what they are doing? Take a look at their website

Looking for a tractor unit with (an electric) PTO? Take a look at TrucksNL

- Buy or sell your truck with DeTruckfinancier - 8 February 2024

- This is how you can use wifi in the truck on the go - 2 January 2024

- The 10 best V8s for sale – October 2023 – TrucksNL - 31 October 2023